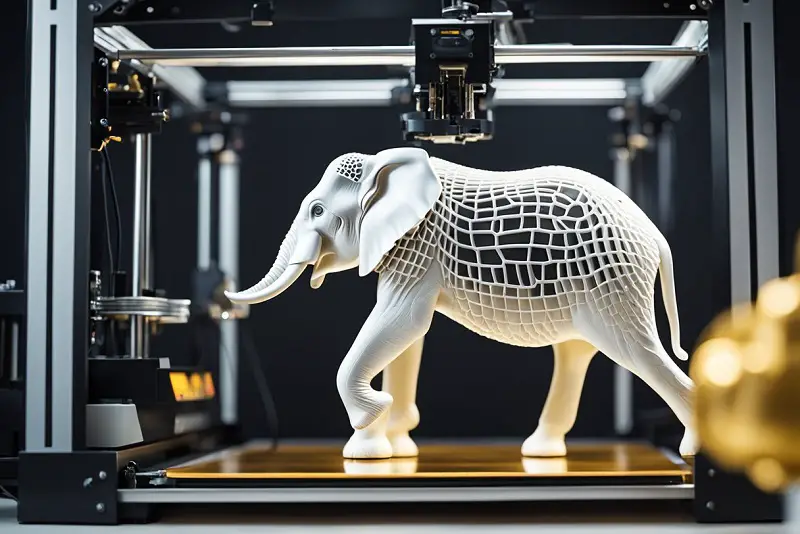

3D printing has grown in popularity over the years due to its versatility and ability to create complex objects with relative ease.

However, despite its numerous benefits, there are still some obstacles that users may encounter during the printing process.

One of these issues is known as elephant’s foot, which can affect the overall appearance and functionality of a 3D print.

Table of Contents

Elephant’s foot occurs when the lower layers of a 3D print are compressed, causing them to bulge outwards, thus giving the print the appearance of an elephant’s foot.

This distortion can be problematic, particularly in taller prints or when precise dimensions are crucial.

It is mainly caused by poorly leveled build plates, excessive weight on lower layers, and incorrect printing settings such as a too small Z-offset or a too high bed temperature.

By understanding the root cause of this issue and implementing the appropriate preventative measures, 3D printing enthusiasts can significantly improve the quality of their prints and overcome the challenges associated with elephant’s foot.

Understanding Elephant Foot in 3D Printing

Elephant Foot: A Basic Overview

Elephant foot is a common issue encountered in 3D printing, where the first layer of a printed object tends to bulge outwards.

It occurs mainly due to the weight of successive layers exerting pressure on the lower layers before they are completely cooled.

Additionally, a poorly leveled building plate can contribute to the development of elephant foot.

Why it is a Problem

Elephant foot can cause severe problems in 3D printing, particularly when printing objects for practical applications.

Not only does it affect the aesthetic appearance of the print, but it can also hinder the proper adhesion of the print to the bed and create an uneven surface, subsequently impacting the object’s functionality.

By understanding the causes of elephant foot, 3D printing enthusiasts can address and prevent this issue, resulting in better print quality and stability.

Key Factors Leading to Elephant Foot

Temperature and Cooling Conditions

The temperature during the 3D printing process greatly influences the occurrence of elephant foot.

When the bed temperature is too high, or cooling is insufficient, it can cause the lower layers to extend outwards due to the pressure from the successive layers above.

To prevent this issue, ensure proper cooling and adjust the bed temperature as needed. For example, PLA filament typically prints best at bed temperatures around 60-70°C.

Filament Types and Their Impact

Different types of filaments can also contribute to elephant foot in 3D prints.

For instance, ABS filament is more prone to warping and may cause elephant foot issues more frequently compared to PLA.

Therefore, it’s essential to understand the properties of the filament you are using and adjust the settings accordingly in your slicing software (such as Cura) to minimize the chances of creating an elephant foot bulge.

Printer Calibration and Bed Level

Poorly calibrated printers and unlevelled beds are common culprits behind the elephant foot problem.

When the nozzle is too close to the bed, it can cause excessive compression of the first layer, leading to the elephant foot effect.

Proper calibration and bed leveling are crucial in preventing this issue.

To fix this, follow these steps:

- Use bed leveling techniques to ensure an even printing surface.

- Adjust the Z-axis to set the correct nozzle height.

- Fine-tune the first layer settings in your slicing software.

- Regularly check your printer for calibration.

By paying close attention to these factors and following best practices in 3D printing, you can significantly reduce the risk of elephant foot in your prints.

3D Printing Settings Influencing Elephant Foot

Essential Role of the First Layer

The first layer plays a critical role in determining the overall quality and appearance of a 3D print.

It’s essential to have an adequately leveled bed, an ideal initial layer height, and the right amount of adhesion.

Beginners often struggle with these settings, which can lead to elephant foot—a common 3D printing ailment where the bottom layers of a print become squished, causing a wider base than intended.

Optimizing first-layer settings, such as initial layer horizontal expansion and initial layer height, can significantly reduce the occurrence of elephant foot.

Weight and Compression Factors

Weight and compression factors also contribute to the elephant foot issue in 3D printing. As the print progresses, the weight of the subsequent layers can compress the initial layers that haven’t yet cooled properly.

This compression forces the initial layers to extend outwards, further worsening the elephant foot effect.

To effectively address weight and compression issues, it’s necessary to fine-tune the printer settings, such as the cooling time and the initial layer horizontal expansion.

Additionally, proper bed leveling and using appropriate print materials can also help mitigate the elephant foot problem.

Potential Fixes for Elephant Foot

Adjusting Temperature and Cooling

One of the crucial factors in fixing elephant foot in 3D printing is the proper management of temperature and cooling.

Insufficient cooling can cause the layers to extend outwards, leading to the elephant foot issue. To prevent this, increase the cooling fan speed and ensure that the printed object is cooled adequately.

Another approach is to decrease the print bed temperature to reduce the possibility of excess filament sticking to the bed.

The Right Use of Filaments

Selecting the suitable filament is essential to avoid elephant foot in 3D prints. Different filaments come with varying recommended print temperatures and bed adhesion requirements.

By choosing the right filament and following the manufacturer’s guidelines, you can achieve the optimal balance between bed adhesion and horizontal expansion, resulting in a flawless print without elephant foot issues.

Adequate Bed Level and Calibration

An improperly leveled bed or inaccurately calibrated Z-offset can contribute to the elephant foot problem. To improve prints, try these steps:

- Level the bed: Proper leveling can help create uniform adhesion across the print surface and reduce elephant foot-like symptoms. Use a leveling tool or paper to adjust each corner of the bed so that the nozzle maintains a consistent height.

- Calibrate the Z-offset: Adjusting the Z-offset can ensure that the nozzle doesn’t dig too deep into the first layer, creating excess adhesion or horizontal expansion. Measure the distance between the nozzle and the bed, and input the correct offset value into your printer’s settings.

- Apply bed adhesion techniques: Applying a bed adhesion solution, like glue or tape, can help create uniform adhesion and minimize the effect on the elephant foot. Be careful not to use too much adhesive, which could worsen the issue.

By combining these fixes and regular maintenance, you can minimize the occurrence of elephant foot in your 3D prints, improving the quality and precision of your projects.

Using Rafts and Chamfers as Solutions

Understanding the Use of Rafts

A common approach to address the elephant foot issue in 3D printing is the use of rafts.

A raft is a sacrificial layer added below the actual print to help support the first layers of the model.

By attaching the bottom layer to a raft, you provide an even surface that lessens the build plate’s friction on the printed object.

Rafts are particularly useful when dealing with a large, flat object, as they can minimize problems related to warping and poor adhesion.

It is important to remember that although rafts can be helpful, they may also increase print time and material usage.

Implementing Chamfers as a Solution

Another way to reduce the occurrence of an elephant foot in 3D printing is by implementing chamfers to your designs.

Chamfers are angled surfaces that replace sharp edges, allowing for a more even distribution of stress and reducing the friction between the build plate and the printed object.

To make use of chamfers, redesign the bottom edges of your model with these angled surfaces. This way, you can achieve a smooth transition between the bottom layer and the rest of the print, reducing the risk of elephant’s foot formation.

Keep in mind that the optimal angle for chamfering depends on your specific printer, material, and project requirements. Hence, experimentation may be necessary to find the best-fit solution.

In conclusion, addressing elephant’s foot in 3D printing can be achieved by using rafts or incorporating chamfers to smoothen the transition between the bottom layer and the rest of the print.

These methods help to minimize friction and provide a more even surface for successful prints.

Practical Applications and Final Tips

Avoiding Future Elephant Foot Issues

Elephant foot is a common issue in 3D printing that occurs when the first few layers of a print appear larger than the higher layers. This can cause practical applications and adhesion problems.

To avoid this issue, it is essential to ensure proper bed adhesion and take preventative measures, such as leveling the print bed properly.

PrusaSlicer can be used to optimize print settings to reduce elephant foot occurrences. For instance, you can decrease the first layer’s width and height to minimize the chances of warping.

Furthermore, maintaining consistent temperatures throughout the print process can play a crucial role in avoiding elephant foot issues.

Eccentric Nut Adjustment

One helpful technique for leveling the print bed and solving elephant foot issues is the adjustment of eccentric nuts.

These nuts, found on the underside of the print bed, can be tightened or loosened to improve bed adhesion and surface contact during the printing process.

To calibrate the print bed, you can print a calibration cube and then adjust the eccentric nuts according to the results.

Continue adjusting and retesting until the printed layers are clean, with no apparent elephant foot issue, ensuring better prints for practical applications.

By taking the time to learn and understand your 3D printer’s leveling and adhesion systems, you can prevent elephant foot issues from happening, allowing for better quality prints and more successful practical applications in the long run.