3D printing has become increasingly popular in recent years, but with its growing popularity comes concerns about safety and potential health risks.

One of the main questions people often ask is whether a 3D printer needs ventilation.

This article aims to shed light on this topic by providing an overview of the importance of proper ventilation and the factors to consider when setting up a 3D printing workspace.

Table of Contents

Ventilation is essential for 3D printers because the printing process can emit fumes and particles that may be harmful if inhaled.

The type of material used for printing, such as ABS or PLA, can impact the level of odor and the quality of fumes produced.

Therefore, it is vital to understand the benefits of proper ventilation and the best practices for your specific 3D printer setup.

In the following sections, we will discuss various strategies for ventilating a 3D printer, specific considerations depending on the type of filament used, and the benefits of using filtration systems such as carbon and HEPA filters to create a safer and cleaner printing environment.

Ventilation Requirement in 3D Printing

3D printers require proper ventilation to ensure the safety and well-being of those using them.

The process of 3D printing involves melting plastic filaments, which release fumes containing harmful particles. These particles can cause nausea, headaches, eye irritation, and adverse effects on the nasal tract.

To address this issue, it’s essential to have a functional ventilation system in place. One effective solution is to place the 3D printer in an enclosure.

This setup helps to contain the fumes and particles that are emitted during the printing process. To enhance the effectiveness of this strategy, it’s essential to use carbon and HEPA filters.

These filters can tackle odors and smaller particles, making the environment safer to work in.

In most cases, opening windows or doors and using an air purifier can provide sufficient ventilation for a single 3D printer.

However, larger 3D printers that operate for extended periods may require more advanced ventilation systems due to the increased accumulation of toxins.

Ensuring proper ventilation is crucial for 3D printing operations. Enclosed workspaces equipped with carbon and HEPA filters, coupled with natural ventilation methods, can mitigate the risks associated with 3D printing fumes.

The specific requirements for optimal enclosure ventilation may vary depending on the size and operating duration of the 3D printer.

Hazards of Insufficient Ventilation

Dust

Dust accumulation can become a problem in spaces where 3D printers are used frequently.

Over time, the dust can settle not only on the printer’s surface but also inside the machine, possibly causing blockages, errors, or reduced print quality.

To maintain the printer’s efficiency and longevity, it’s crucial to have good ventilation in the workspace to help reduce dust buildup and decrease the need for frequent cleaning.

Fumes

When 3D printers operate, they emit fumes, some of which can be toxic. These fumes contain volatile organic compounds (VOCs) and other harmful particles that can lead to nausea, headaches, and irritation of the eyes and nasal tract.

Examples of toxic substances released during the printing process include styrene, a known carcinogen.

Ensuring proper ventilation in the workspace helps reduce the risk of exposure to these fumes and improves overall air quality.

Temperature

3D printers generate heat, and without sufficient ventilation, the temperature in the workspace can become uncomfortable.

High temperatures may also lead to the release of plastic nanoparticles.

Good ventilation helps maintain a stable temperature in the workspace, allowing for safer and more comfortable working conditions while also minimizing the potential health effects associated with exposure to elevated temperatures and nanoparticle emissions.

Types of 3D Printer Enclosures

A 3D printer enclosure is an essential component in the 3D printing process, as it helps maintain a stable environment and protects users from potentially harmful emissions.

There are several types of enclosures to choose from depending on the specific requirements of the printer and the materials being used.

One common type of 3D printer enclosure is the ventilated enclosure, which aims to prevent fumes and particulates from being released into the room while ensuring a controlled environment for the printer.

This type of enclosure typically has a fan or air filter to circulate and purify the air, providing effective filtration and reducing the exposure to harmful VOCs and particles.

A ventilated enclosure is often recommended to eliminate emissions, especially when printing with materials like ABS and resin that are known to produce more fumes.

Another option is the sealed enclosure, which is designed to maintain a constant temperature and humidity level for optimal 3D printing results.

This type of enclosure prevents drafts and temperature fluctuations that can adversely affect the quality of printed objects.

Although they don’t have active ventilation systems, these enclosures are generally sealed well enough to limit the escape of emissions to a minimum.

Many people opt for DIY enclosures. Using readily available materials such as acrylic sheets, wood, or even cardboard, they can create a custom enclosure tailored to their printer’s specifications.

This approach allows for personalized design with features like lights, vents, or air filters. However, it’s essential to ensure proper handling of electronics and sufficient ventilation when assembling a DIY enclosure.

Lastly, some 3D printer manufacturers offer dedicated enclosed 3D printers or add-on enclosures explicitly designed for their printers.

These enclosures often come with built-in features such as HEPA filters, activated carbon filters, or air purifiers, providing the best results regarding both safety and print quality.

Although these may be more expensive, they usually offer a seamless integration, ensuring compatibility and ease of use.

In conclusion, choosing the right type of 3D printer enclosure depends on various factors, including the printer’s make and model, the types of materials being printed, and personal preferences for specific features.

These aspects will help you select the most suitable enclosure option for a safe and productive 3D printing experience.

Ventilation Solutions for 3D Printers

3D printers can emit fumes, which may be harmful if inhaled. Proper ventilation is essential to ensure the safety of users and the quality of prints.

There are several ways to achieve proper ventilation for your 3D printer, and some of the most common methods are discussed below.

Placing your 3D printer near a window or open door can provide natural ventilation, allowing fumes to dissipate into the open air.

This is a simple and cost-effective solution, but it may not be sufficient for printers with high fume emissions or in rooms with poor airflow.

Using air purifiers with HEPA filters and carbon filters is another excellent option. HEPA filters are designed to capture fine particles, while carbon filters help reduce odors and harmful gases.

This combination efficiently tackles the emissions produced by a 3D printer and could be a great addition to your workstation for improved air quality.

Air extractors or exhaust fans can also be a viable solution for 3D printer ventilation. These devices actively pull the fumes and particles away from the printer, sending them outside or through a filtration system.

Installing an exhaust fan near your 3D printer ensures a constant flow of clean air, significantly reducing the risk of inhaling harmful emissions.

Lastly, enclosing your 3D printer can help in managing fumes. By placing the printer inside an enclosure with a filtration system or an air extractor, you can minimize the fumes and particulates emitted into the surrounding environment.

Various solutions are available to provide adequate ventilation for your 3D printer.

It’s essential to choose a method that aligns with your printer’s requirements and your workspace conditions to ensure a safe and effective printing experience.

Can a Room be Too Hot for a 3D Printer?

Yes, a room can be too hot for a 3D printer. High room temperatures can affect the quality of 3D prints, especially with materials like PLA, which have a lower melting point.

When the ambient temperature is too high, the cooling process of the extruded filament can be hampered, causing the prints to warp or lose their shape.

On the other hand, a 3D printer can also be affected by a room that is too cold. Drafts or rapid temperature fluctuations may lead to print failure or other issues.

An optimal environment for 3D printing involves maintaining a consistent temperature with minimal drafts.

One way to mitigate temperature-related issues is to use an enclosure, which can help regulate the temperature around the 3D printer and protect it from drafts.

Another vital aspect to consider is proper ventilation, especially when working with materials that emit fumes or particles that may harm human health.

In summary, it is essential to maintain an appropriate temperature in the room where a 3D printer is being used for optimal print quality and to avoid potential health hazards.

An enclosure and proper ventilation system can help create a suitable environment for your 3D printer to produce high-quality prints.

Best Locations for 3D Printing

When setting up your 3D printer, it’s essential to choose an appropriate location to ensure both safety and efficiency.

A well-ventilated area is crucial, as 3D printers generate volatile organic compounds (VOCs) and particulate during the printing process. In this section, we will discuss various locations that can serve as suitable environments for your 3D printer.

An open area or open space can be an excellent choice for 3D printing. These spaces typically offer better natural ventilation, allowing fumes to disperse quickly.

Moreover, outdoor spaces also have the advantage of providing additional workspace, reducing the risk of cluttering your living area.

Garages are another ideal option for setting up a 3D printer. Garages usually have windows or proper cross ventilation, ensuring safety from harmful fumes.

Additionally, garages often have extra workspaces and can be easily modified to accommodate your 3D printer, allowing for uninterrupted printing sessions.

A workshop or dedicated workspace also serves as a great location for your 3D printer. Workshops can be specially arranged to promote optimal airflow and can be equipped with air filters and air extractors if needed.

Moreover, having a designated space for 3D printing keeps the equipment and materials organized.

While a bedroom or living room may be more accessible, they are not the best choice for 3D printing due to the lack of proper ventilation and the potential impact on your living space.

Although it is possible to set up a 3D printer in these rooms, extra care must be taken to ensure proper ventilation, such as opening windows and using air purifiers.

In conclusion, when deciding on the best location for your 3D printer, prioritizing proper ventilation and workspaces will result in a safer and more efficient printing process.

Consider open areas, garages, and workshops, and weigh their pros and cons before deciding to ensure a successful 3D printing experience.

3D Printing Safety Measures

One of the primary concerns when operating a 3D printer is safety. Ensuring a well-ventilated environment is essential in preventing the build-up of harmful fumes and particles produced during the 3D printing process.

Opening a window or door and using an air purifier can provide enough ventilation in most cases.

However, larger 3D printers working for extended periods may require more substantial ventilation systems to maintain a safe and healthy workspace.

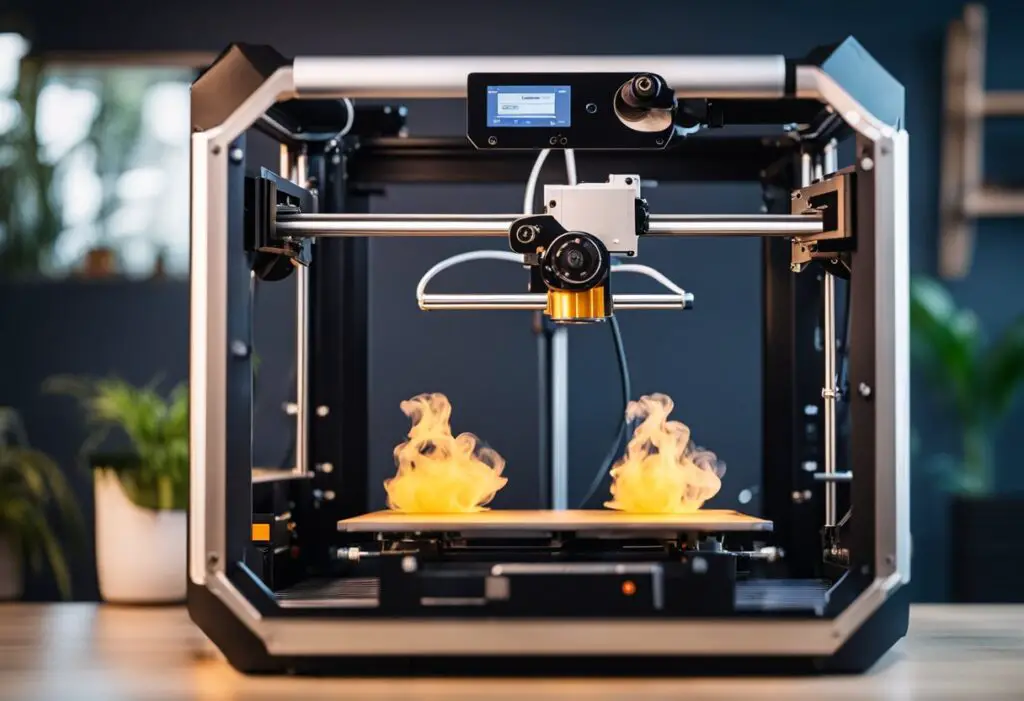

Another significant safety aspect that should not be overlooked is the potential fire hazard associated with 3D printing.

To minimize this risk, always choose a printer with built-in safety features, such as thermal runaway protection and automatic shutdown in case of overheating.

Additionally, it is essential to place your 3D printer on a stable, non-flammable surface and keep any flammable objects away from the device during operation.

For a safer 3D printing experience, always follow the manufacturer’s guidelines for proper use and maintenance.

By acknowledging the hazards associated with 3D printing and taking necessary precautions, you can ensure a secure environment for yourself, your workplace, and your community.

Impact of Filament Types on Ventilation

3D printers use various types of filaments, and each type has a unique impact on the need for ventilation. The two most common filament materials are PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene).

PLA is considered a safer option as it is made from renewable resources like cornstarch.

However, despite being biodegradable and relatively safe to use, PLA still emits some fumes during the printing process, and sufficient ventilation is essential to avoid exposure to respirable particles.

On the other hand, ABS is derived from petroleum products and releases more odors and fumes.

These fumes contain volatile organic compounds (VOCs) and styrene, a potentially harmful substance. As a result, proper ventilation is crucial when using ABS filaments to protect users from toxic chemicals.

Other filament materials, such as PETG, TPU, and nylon, also emit odors and chemicals during the printing process.

Each material requires a different level of ventilation, but it is always essential to ensure adequate airflow to minimize fume exposure.

A well-ventilated workspace with an active extraction system can significantly reduce the risks of inhaling harmful chemicals.

Using carbon filters and HEPA filters is highly recommended.

It’s also essential to choose the appropriate filament material for your specific needs and prioritize safety over other factors.