3D printing has emerged as a groundbreaking technology, revolutionizing numerous industries and changing the way we create objects.

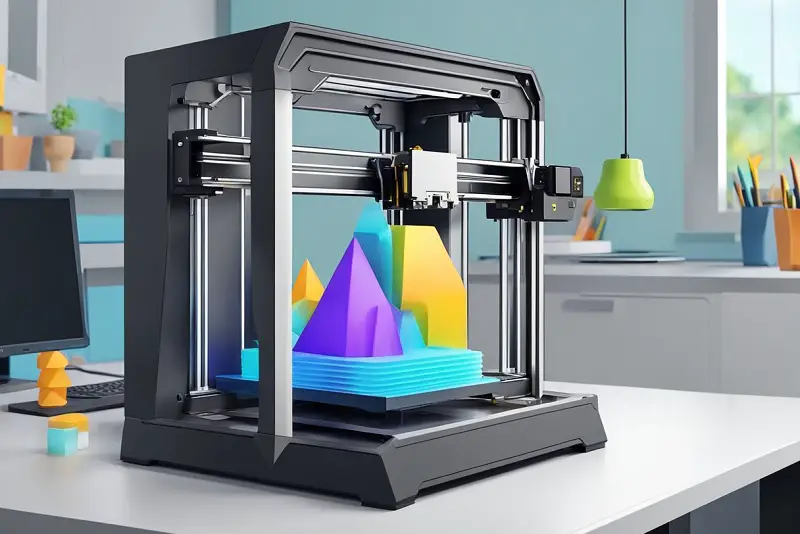

This additive manufacturing process involves the layering of materials to produce three-dimensional creations through the use of computer-aided design (CAD) software.

From automotive parts to intricate art pieces, the potential applications of 3D printing are vast and ever-growing.

As a versatile technology, 3D printing has made significant strides in sectors such as healthcare, aerospace, construction, and fashion.

The ability to rapidly prototype designs, create customized items, and develop intricate structures has positioned this innovative process as an indispensable tool for various professionals and enthusiasts.

Exploring the numerous ways 3D printing is employed across multiple industries offers valuable insight into the transformative impact it has on our lives.

Table of Contents

Applications of 3D Printing

3D printing has become an essential tool for various industries, revolutionizing manufacturing, and prototyping processes. Engineers utilize this technology for designing intricate metal parts with high precision and accuracy, enhancing the functionality of various products.

From automotive to aerospace engineering, 3D printing has significantly streamlined the manufacturing process.

Within the medical field, 3D printing has paved the way for advanced implant technology. Dental professionals utilize it for creating accurate dental prosthetics with custom fits.

This innovation has also expanded into the bioprinting realm, where scientists explore 3D bioprinting for the creation and repair of human tissues. Patients find great comfort and improved outcomes in using 3D-printed orthopedic prosthetics, making the technology an indispensable tool for the healthcare industry.

On a more personal level, 3D printing has found its way into the fashion and jewelry sectors. Designers now have the capability to create intricate shoes and clothing items tailored to individual measurements.

Meanwhile, jewelers can produce sophisticated and precise designs for custom jewelry pieces, adding a unique touch to each creation.

One of the more surprising applications of 3D printing lies in the culinary arts. Companies now produce 3D-printed chocolate and other food items. These delightfully detailed edibles expand the boundaries of creativity, bringing an exciting new dimension to the world of food as art.

The construction and architecture industries have also embraced the potential of 3D printing. With the ability to create concrete structures and complex glass designs, architects can now fully realize their artistic vision. Moreover, the technology offers the possibility to create eco-friendly, affordable housing solutions.

In summary, 3D printing has emerged as a versatile technology that has profoundly impacted numerous industries. Its widespread use, from essential medical equipment to fashionable accessories, has made it an invaluable tool in the journey of innovation and progress.

3D Printing in Medicine

3D printing has been transforming the medical industry since its inception in the 1980s. This technology has shown great potential in various applications, from the development of replacement organs and prosthetics to creating medical equipment.

Let’s look at some specific uses of 3D printing in the field of medicine.

One of the main applications of 3D printing in medicine is the creation of custom prosthetics. By using digital designs, professionals can design and print prosthetic limbs tailored to individual patients’ needs.

This personalization improves the comfort and functionality of the devices, making it easier for patients to navigate their daily lives.

Implants, like prosthetics, can also be tailored to individual patients.

Using 3D printing, doctors now have the ability to create customized implants with complex geometries that match a patient’s unique anatomy.

This customization leads to better-fitting implants that can integrate more seamlessly with the body, improving patient outcomes and comfort.

3D bioprinting is another exciting development in this field. By using bio-inks, which consist of living cells, researchers and medical professionals can print a variety of tissues and organs for potential transplant.

While still in the early stages of development, bioprinting has shown promise in addressing the shortage of donor organs and providing personalized healthcare solutions.

Additionally, 3D printing can play a role in pharmaceutical research and drug delivery. Customizing drug dosage forms and delivery systems helps improve patient adherence and the effectiveness of medications.

An example of this application is a 3D-printed epilepsy treatment that delivers a large dose of the active ingredient quickly, making it easier for patients to use.

In summary, 3D printing offers numerous benefits in medicine, from creating customized prosthetics and implants to the potential of bioprinting organs and revolutionizing drug delivery systems.

As technology continues to advance, it is likely that the applications and impact of 3D printing in medicine will only keep growing.

3D Printing in Manufacturing

3D printing, also known as additive manufacturing, is transforming the engineering and manufacturing landscape.

Companies like 3D Systems have pioneered this technology, making it possible to produce complex geometries and designs that were once impossible with traditional methods.

The manufacturing process begins with a digital 3D model, which is then sliced into layers to guide the printer.

Material is added layer by layer, fusing each consecutive layer until the part is complete. This approach minimizes material waste and improves scalability for small-scale production runs.

One major advantage of 3D printing is its ability to produce highly accurate parts. This is particularly important in industries such as aerospace, automotive, and medical, where precision is crucial.

Through a combination of advanced software and refined printing techniques, 3D printers can achieve tolerances within microns of the desired dimensions.

Metal parts, which were once the domain of traditional machining, are now increasingly produced using 3D printing.

Metal additive manufacturing enables the creation of intricate, lightweight components that can withstand high temperatures and stress. Among the materials commonly used are titanium, aluminum, and stainless steel.

In conclusion, 3D printing offers a range of benefits for the manufacturing process, from increased accuracy to the production of complex and sophisticated components.

With companies like 3D Systems leading the charge, the future of manufacturing is set to be revolutionized by this innovative technology.

3D Printing in Fashion and Jewelry

3D printing is revolutionizing the fashion and jewelry industries by providing designers with unparalleled creative freedom and rapid prototyping capabilities.

In fashion, designers use 3D printing technology to create intricate patterns and accent pieces not achievable with traditional manufacturing methods.

This has led to the creation of unique clothing items, shoes, and accessories made from a variety of materials. They often make use of flexible materials like TPU to add an extra dimension to their designs.

The jewelry industry has also embraced 3D printing, using it mainly for design and prototyping purposes.

The most prevalent method involves using castable wax resin in 3D printers to create intricate designs tailored to client’s preferences and even quickly implement changes when necessary.

This innovative approach offers increased customization and reduces production time compared to traditional methods like lost-wax casting.

One of the advantages of 3D printing in fashion and jewelry is that both industries can create more sustainable and eco-friendly production processes.

Custom-made items minimize waste and ensure that materials are used efficiently. Furthermore, designers can experiment with biodegradable or recycled materials to incorporate environmentally-friendly practices.

In addition to clothing and jewelry, 3D printing is being used to create stunning fashion accessories such as bracelets, rings, brooches, necklaces, and pendants with resin 3D printers, giving life to futuristic designs and innovation in accessory design.

The use of 3D printing in the fashion and jewelry industries is not just limited to the design aspects. It also expands the opportunity to customize and create personalized items, catering to a broader audience with specific and diverse preferences.

Ultimately, this technology paves the way for new trends and a shift towards more innovative and sustainable practices in both industries.

Innovative 3D Printing Applications

3D printing has come a long way since its inception. Today, it is used in a variety of industries, showing its versatility and potential for innovation.

Let’s explore some intriguing applications of 3D printing across different sectors.

In the food industry, 3D printing has made it possible to print customizable meals and intricate designs. For instance, chocolate has become a popular medium for artists and chefs, enabling them to create unique, eye-catching desserts.

Even glass objects can be 3D printed, opening up a new world of possibilities in decorative art, functional items, and much more.

The construction field has seen great advancements, as well. The use of concrete in 3D printing has led to the development of innovative architecture and building structures.

This technique can aid in creating affordable housing, reducing environmental impacts, and accelerating construction processes.

Some other notable applications of 3D printing include:

- Biomedical: 3D printing helps in creating custom prosthetics, implants, and other medical devices.

- Aerospace: Manufacturing lightweight and complex parts for aircraft using 3D printing saves time and improves efficiency.

These examples demonstrate the extensive applications of 3D printing, transforming industries with its versatility and sparking countless innovations. As technology advances, 3D printing will continue to shape the future in exciting ways.

How is 3D Printing Used: A Recap

3D printing, also known as additive manufacturing, has emerged as a powerful technology with a wide range of applications.

By building objects layer by layer from a digital file, 3D printing has transformed numerous industries and improved efficiency in product development.

One major use of 3D printing is in the field of prosthetics. This technology has revolutionized the process of creating tailored prosthetics by making it more straightforward and efficient.

Custom prosthetics can be modeled using computer-aided design (CAD) software and then fabricated with 3D printers, significantly reducing the time and effort required in traditional processes.

Another exciting application of 3D printing is in construction. NASA, for example, has partnered with a construction company called ICON to develop 3D-printed structures for potential moon homes for astronauts by 2040.

This innovative approach could lead to more efficient and sustainable construction methods.

In terms of resource efficiency, 3D printing stands out due to its ability to use materials more effectively.

Traditional subtractive manufacturing processes often result in material waste, while estimates show that about 98% of the material used in 3D printing ends up in the finished products.

Medical researchers are also exploring the potential of 3D printing. Scientists at Oxford University have successfully 3D-printed human stem cells that could help repair brain injuries.

These stem cells were even implanted into the brains of mice, opening up new possibilities and understanding for the future of medicine.

In summary, 3D printing has a wide range of applications, from prosthetics and construction to resource efficiency and medical advancements.

As the technology continues to develop, it’s likely we’ll see even more innovative uses for 3D printing in the future.