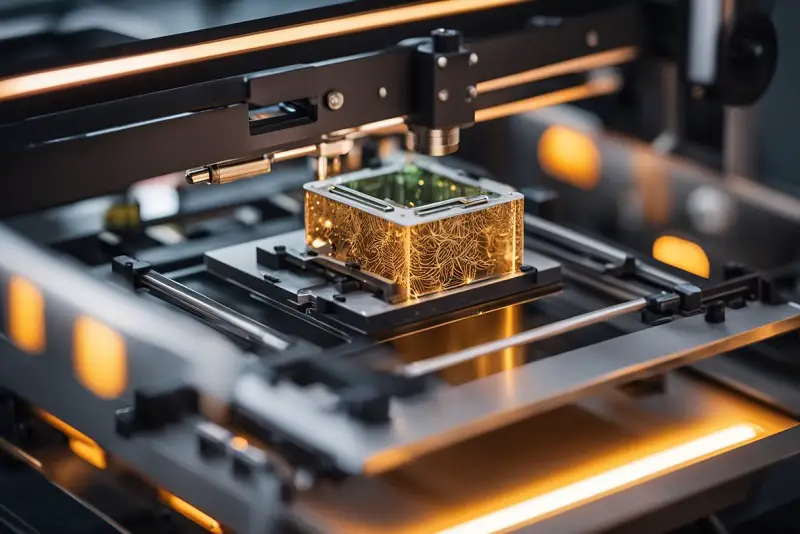

3D printing has revolutionized various industries, including manufacturing and medicine, by easily creating complex and customized objects.

Selecting the right material is crucial to achieve such versatility, and polymers have quickly become a popular choice in this realm.

This article will explore the types of polymers used in 3D printing and their unique properties.

Table of Contents

Polymer 3D printing uses plastic materials that offer diverse properties and capabilities, catering to the needs of different applications.

One of the primary benefits of using polymers in 3D printing is their cost-effectiveness, enabling the production of functional parts without breaking the bank.

In the upcoming sections, we will delve into the various polymer materials available for 3D printing and the factors to consider when choosing the appropriate polymer for a specific project.

Stay tuned to learn more about the exciting world of polymer 3D printing.

What is Polymer 3D Printing?

Polymer 3D printing is a rapidly growing technology that utilizes various polymers to create complex structures and components.

This method allows designers and engineers to transform digital models into physical objects layer by layer.

It offers numerous advantages, including the ability to create customizable parts, produce intricate designs, and improve efficiency in the manufacturing process.

There are several types of 3D printing technologies designed explicitly for polymers, such as Fused Filament Fabrication (FFF), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Each technique has its unique process and material requirements, making them suitable for different applications.

For example, SLA is known for its excellent surface finish, while FFF is popular for its ease of use and affordability.

Many commercially available polymers can be used in 3D printing, such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polycarbonate (PC), poly ether ester ketone (PEEK), polyetherimide (ULTEM), and thermoplastic elastomers (TPE).

These materials offer diverse characteristics, allowing for various applications, from creating prototypes to producing functional parts for various industries, including aerospace, automotive, and medical fields.

In recent years, advancements in polymer 3D printing have led to significant improvements in the quality and performance of printed components.

However, there are still challenges to overcome, such as limited material availability and further enhancements in the quality of manufactured products.

Despite these obstacles, the potential of polymer 3D printing continues to grow, and its applications are steadily expanding across various industries.

Common Polymers Used in 3D Printing

Several polymers are commonly used in 3D printing, each with unique properties and applications.

In this section, we’ll cover elastomers, Ultem, and PEEK, as well as discuss their typical applications and advantages.

Elastomers

Elastomers, such as thermoplastic polyurethane (TPU) and polyamide (PA), are versatile materials often used in 3D printing.

TPU is known for its flexibility and durability, making it suitable for a wide range of applications, including wearables, automotive components, and medical devices.

Polyamide, often referred to as nylon, is another common elastomer used in 3D printing, boasting exceptional toughness and resistance to high temperatures and impacts.

Polyamide is available in various forms, such as PA11 and PA12, each with slightly different characteristics and applications.

Ultem

Ultem, or polyetherimide (PEI), is a high-performance polymer known for its excellent thermal, mechanical, and chemical resistance properties.

Ultem is a popular choice for aerospace, automotive, and medical industries because of its ability to withstand harsh environments and maintain its mechanical properties at high temperatures.

Ultem has a high strength-to-weight ratio and excellent flame retardance, making it ideal for applications that require lightweight, strong, and heat-resistant materials.

PEEK

PEEK, or polyether ether ketone, is another high-performance polymer that offers exceptional mechanical, thermal, and chemical resistance.

Like Ultem, PEEK is an excellent choice for aerospace, automotive, and medical applications due to its combination of strength, lightweight, and temperature resistance.

It has a higher melting temperature than Ultem and provides superior chemical resistance, enabling its use in highly demanding applications.

Overall, PEEK is known for its durability, high resistance to wear and fatigue, and biocompatibility.

In summary, 3D printing provides a wide range of flexible polymers applicable across various industries, each designed to leverage unique properties in a range of applications.

From elastomers like TPU and polyamides to high-performance polymers like Ultem and PEEK, the possibilities in 3D printing continue to expand, enabling new advancements in diverse applications.

Properties of 3D Printing Polymers

Mechanical Properties

3D printing polymers exhibit various mechanical properties, depending on the polymer type used and the 3D printing process.

Common mechanical properties include tensile strength, elasticity, and impact resistance. These properties can be tailored for specific applications by selecting appropriate polymers and adjusting the printing process.

For example, fused deposition modeling (FDM) utilizes extrusion-based printing, which can influence the mechanical properties of the final object.

Electrical Properties

In addition to their mechanical properties, some 3D printing polymers are conductive, offering interesting applications in electronics and wearable devices.

One example is PEDOT, a conductive polymer that can be 3D printed using a paste-like ink created by cryogenic freezing.

The electrical properties of printed parts can be tuned by adjusting factors such as the concentration of conductive particles in the polymer matrix.

Rheological Properties

The rheological properties of 3D printing polymers play an essential role in determining the printability and final characteristics of the printed object.

These properties, such as viscosity and shear thinning, must be carefully controlled to ensure the proper flow and adhesion of the material during the 3D printing process.

Modifying the rheological properties of a polymer can lead to improved resolution, surface finish, and reduced need for post-processing steps.

Achieving the desired rheological properties often involves fine-tuning the polymer’s formulation and processing conditions, which can impact the finished product’s mechanical and electrical properties.

What polymer is 3D printing resin?

3D printing resin is a liquid chemical composed mainly of photo-sensitive polymers and other ingredients.

When exposed to UV light, such as in a resin 3D printer, the resin solidifies and forms the final print.

Polymer 3D printing has rapidly advanced in recent years, offering versatile material selections and a wide range of design possibilities.

Polymer printing uses multiple processes, including extrusion, resin, and powder 3D printing.

Some popular 3D printing processes that build objects layer by layer without molds or machining are material extrusion, vat photopolymerization, and material jetting.

The most common polymers used in 3D printing resins are acrylate- and methacrylate-based.

These materials offer a balance of durability, flexibility, and precision, making them ideal for a diverse range of applications, from prototyping to producing functional parts.

In addition to the standard resins, specialized resins are available for specific requirements, such as flexible, high-temperature, or biocompatible resins.

As the field of 3D printing continues to expand, new advancements in polymer formulations will further enhance the capabilities of this versatile technology.

Advancements in 3D Printing Polymers

Additive manufacturing has come a long way in recent years, with significant advancements in 3D printing polymers.

The ability to create custom, complex structures using a wide variety of polymer materials has revolutionized industries and introduced new opportunities for innovation.

One of the key developments in 3D printing polymers is the growing range of materials available for use.

Researchers are continually working to create new combinations of thermoplastic polymers, strengthening properties to suit various applications.

This includes materials with enhanced durability, flexibility, and heat resistance, allowing for even more possibilities in the design and construction of 3D printed objects.

For example, this comprehensive review can find some recent advancements in polymer composites for 3D printing.

Technological trends in 3D printing with polymers also involve improving the efficiency and accuracy of the manufacturing process.

Developments such as the refinement of modeling software and the enhancement of printing techniques have made it possible to achieve a better level of customization in 3D printed objects without compromising on the quality or functionality of the final product.

Integration of nanocomposite materials has also shown promising improvements in properties, as discussed in this recent study.

Efficiency plays a significant role in the future of 3D printing polymers, as high-speed 3D printers are becoming increasingly accessible.

The development of faster and more accurate printers leads to reduced production times and contributes to a lower environmental impact and reduced costs.

The adoption of these high-efficiency printers will likely become more widespread as the technology becomes more affordable.

In conclusion, the advancements in 3D printing polymers, coupled with the ever-growing range of materials and improved technology, are creating exciting opportunities for the future of additive manufacturing.

Customization, high efficiency, and ongoing developments in the field are positioning 3D printing polymers as a driving force in reshaping industries and offering innovative solutions for design, production, and countless applications.

What is the Strongest Polymer for 3D Printing?

Polyether Ether Ketone (PEEK) is widely considered to be the strongest thermoplastic polymer for 3D printing.

PEEK is suitable for demanding applications across various industries such as aerospace, automotive, and medical, boasting exceptional mechanical properties, high thermal stability, and chemical resistance.

Apart from PEEK, polycarbonate (PC) is another prominent material known for its high tensile strength, high impact, and heat resistance properties.

Though it offers impressive performance, PC can be challenging to print with due to its relatively high extrusion and build plate temperature requirements.

Other materials such as Polylactic Acid (PLA), Tough PLA, Acrylonitrile Butadiene Styrene (ABS), glycol-modified polyethylene terephthalate (PET-G), Nylon, and Polypropylene (PP) also exhibit strong properties.

When choosing the best material for your 3D printing requirements, it’s essential to clearly understand the required strength, flexibility, temperature resistance, and other essential attributes needed for your specific project.

Moreover, special engineering resins, such as Liqcreate Strong-X, offer incredible toughness and exceptional tensile strength.

These resins are compatible with various resin 3D printing technologies, including SLA, MSLA, and DLP.

What Polymer is Used in 3D Printing: The Essentials

3D printing has revolutionized many industries, and one major contributor to this revolution is the variety of polymers used in the process.

Polymers offer a broad range of material characteristics and processing approaches, making them ideal for many applications, especially in the medical field.

One popular polymer used in 3D printing is poly (3,4-ethylenedioxythiophene) sulfonate (PEDOT).

This high-performance conducting polymer ink is suitable for creating various electrical components and devices.

Another common polymer used in 3D printing is photopolymer resin, which is often utilized with Stereolithography (SLA) technology.

SLA is known for producing high-quality parts with an excellent surface finish, making it ideal for intricate designs and prototypes.

In powder bed fusion technology, which uses laser or electron beams to selectively melt powder material layer by layer, thermoplastic powders, such as nylon or polyamide, are often used.

These materials provide excellent mechanical properties and resistance to wear, making them suitable for functional parts and prototypes.

Despite the numerous polymer options available for 3D printing, some challenges remain, such as limited material availability and suboptimal quality of manufactured products.

However, ongoing research and development continue to push the boundaries and expand the capabilities of 3D printed polymer components.